Perma-Chink Systems, Inc

Log & Timber Home Care Experts

Perma-Chink Systems, Inc

Log & Timber Home Care Experts

Michael

While we call our pigmented finishes “stains,” in reality they behave more like water-based paints than traditional oil-based stains. The word stain itself implies that the wood fibers become “stained” with the pigments contained in the product, whereas water-based finishes form a film that covers the wood fibers without actually coloring or “staining” them.

Every summer we receive calls about small flying insects making holes in the exterior surfaces of logs. They are usually described as tiny flies, bees or flying ants, but in fact these insects are small parasitic wasps that are about the size of a fruit fly or large gnat. There are literally hundreds of parasitic wasp species and some of them specialize in parasitizing beetle larvae including wood boring beetles. They can be seen going in and out of existing beetle emergence holes looking for live beetle larvae to lay their eggs on.

One of the best tools an applicator or homeowner can have in their possession is a moisture meter. In addition to finding trouble spots due to water infiltration, it can also help determine if the surface of logs are dry enough to seal or finish.

Some of the most vulnerable areas of a log home are the corner log ends. This is because the cross section end grain is exposed and the ends often stick out beyond the walls, allowing sunlight, wind, rain, snow, and ice to wear away the stain and expose bare wood. Logs can safely absorb large quantities of water before reaching moisture content levels that will be inviting for decay fungi.

The exposed end grain acts like small straws sucking water into the log, giving rot and decay an opportunity to start eating away the wood. In addition, wood cracks and checks are prone to start at the ends. If left unprotected long enough, log or log corner replacement may eventually be required.

Being aware of the susceptibility of log ends to weathering, rot and decay, we developed Log End Seal™, a clear polymer finish that prevents water from penetrating into log ends and provides a layer of protection against log end damage. Although it is a sealer, Log End Seal is designed to allow moisture already in the wood to slowly escape. This helps reduce those large checks that often form on log ends.

To prevent excessive moisture absorption, Perma-Chink Systems developed Log End Seal, a product unique and specially formulated to protect log ends. Although Log End Seal is a fairly simple and easy product to use, there are some tips that can help you avoid problems especially in the fall when cooler temperatures slow down the curing process.

The basic steps of applying Log End Seal:

The basic steps of applying Log End Seal:

- Sand log ends with 60-grit sanding disc or paper

- Apply Lifeline finish

- Apply Log End Seal

- Apply Advance Topcoat

Let’s take a more detailed look at the individual application steps.

Step 1: Sand log ends with a sanding disc or sandpaper (60-grit). Log End Seal requires application in one (1) thin coat. In order to attain a thin coat, the log ends need to be sanded fairly smooth. If the ends are not smooth, the rough surface texture will prevent a thin coat application. This will result in thicker film, and will take longer to cure.

Step 2: Apply the Lifeline finish on the sanded ends, ensuring complete coverage. Allow time for the finish to dry before applying Log End Seal.

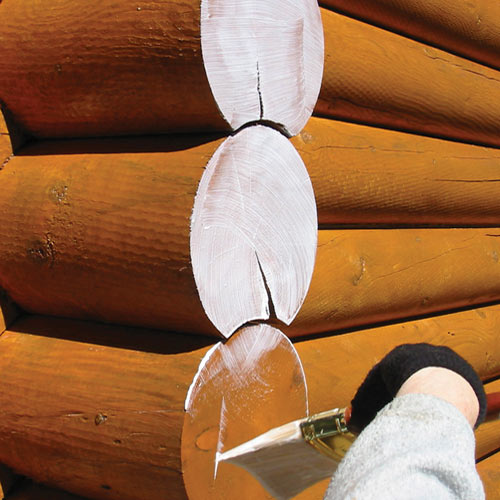

Step 3: Apply one thin coat of Log End Seal to the log ends, after the Lifeline finish has dried. Log End Seal white until it is fully cured, and if it gets wet during the curing process, the white color can last for several weeks. If Log End Seal is applied in a thick coat and gets wet, it may take several weeks or months for it to become completely clear and transparent. This is the most frequent cause of complaint from our customers. Eventually it will cure and become clear, but in the meantime, the log ends on your home will have a white haze.

Tip: Choosing the right application tool can help prevent applying too thick a film. Rather than using a standard paintbrush, a paint pad or sponge brush works best. Since Log End Seal is thick and viscous, some people prefer to apply Log End Seal with a wide-blade trowel. Any of these tools will work as long as the Log End Seal is applied in a thin coat.

Tip: Choosing the right application tool can help prevent applying too thick a film. Rather than using a standard paintbrush, a paint pad or sponge brush works best. Since Log End Seal is thick and viscous, some people prefer to apply Log End Seal with a wide-blade trowel. Any of these tools will work as long as the Log End Seal is applied in a thin coat.

Step 4: Finally, apply a single coat of Lifeline Advance™ to help protect the Log End Seal surface to remain clean and dry.

Coverage Rate: When applied correctly, one gallon of Log End Seal goes a long way. One gallon covers 30 to 40 square feet, which equates to 100 eight-inch diameter log ends, or 180 six-inch diameter log ends.

Have you ever seen the exterior of a home that has turned black? Almost without fail it’s the result of using a stain that contained linseed oil. Linseed oil is a yellowish oil derived from the dried seeds of flax plants, which is the reason it is also called flax seed oil.

For several years our Lifeline™ Advance Topcoats have been an integral part of our exterior finish systems. In addition to prolonging the life of the finish system, Advance Topcoats help keep the exterior surfaces free of dust and dirt, and make them easier to clean. That’s because Advance is designed specifically as a topcoat. Unlike most topcoats on the market, Advance is not just a non-pigmented version of our Lifeline stain. Because we formulate our stains for maximum color retention and adhesion when applied to bare wood, we use an entirely different formulation to meet the performance criteria important in a clear topcoat.

Both M-Balm® and E-Wood® are two component epoxies that are used for repairing soft spots, rot pockets and other types of defects in logs and timbers. Although they can be used individually, they are typically applied as a pair with each product playing a specific role.

It is virtually impossible to prevent logs from developing cracks and checks as they age and dry. That is because as wood seasons, mechanical stresses build up until the surface stress becomes so great that the wood cracks. We call these stress cracks “checks.”

Since interior finishes are not exposed to rain, snow, wind, and direct sunlight, long term resistance to weather is not an issue, and you have more flexibility when choosing the color and appearance of your interior wood surfaces. However, there are some parameters that need to be followed to assure you obtain the benefits of an interior finish, such as preventing odor absorption and making the walls easy to keep clean, while getting the look you desire as well.

All Lifeline™ finishes are water-based, film-forming coatings. Although we refer to our pigmented coatings as “stains,” they do not “colorize” the wood like penetrating oil-based products; they form a film on the surface of the wood, thus protecting the underlying wood from the effects of wind, water, and sunlight. Since they form a film on top of the wood, they rely on proper surface preparation to ensure good adhesion.

New Age Blast Media Available Sizes

Call 1-800-548-3554 to Order

Features

- Made from recycled glass

- Superior to corn, walnut, sand or soda media