If water gets behind the film there is a chance for the finish to blister, lose its adhesion, and peel off. Most people seem to understand and accept the consequences of water getting behind paint but they have a difficult time accepting that a “stain” can behave in the same manner. This not only applies to water-based products like Lifeline™, but can also happen with oil-based finishes if the surface is not properly prepared or the finish is not correctly applied.

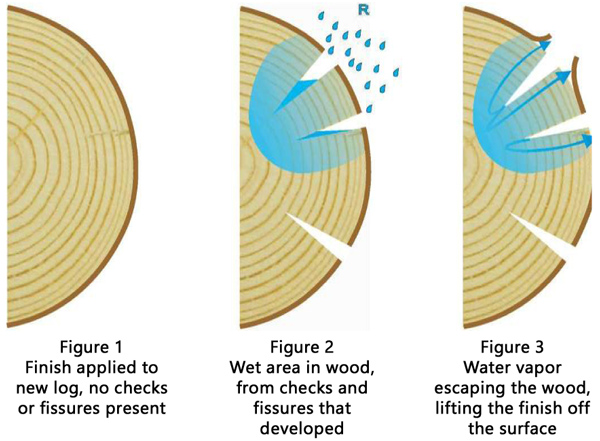

Most peeling issues are associated with finishes on new logs or new log siding. When the finish is first applied the surface of the logs or siding is intact [Figure 1]. Later on fissures and checks may develop, especially on the sunny walls, which allow rain water to get into the wood behind the finish [Figure 2]. Gravity plays a role in this, since most peeling occurs below the checks and fissures. When the sun comes out and beats on the wall, the water turns to water vapor and pushes the finish right off the surface [Figure 3].

Two additional factors play a role in the susceptibility of a finish to peeling. The first is vapor permeability. The more vapor permeable a finish is, the less likely it will peel. However, even vapor permeable finishes like Lifeline can peel when applied too thickly, or if too many coats of finish are applied. That’s why we recommend thin coats of finish and maintenance coats of Advance™ topcoat only as needed! It is much more important to keep the surface clean than it is to apply an additional coat of topcoat every two to three years. Every coat that is applied will further reduce the vapor permeability to the point where water vapor can no longer escape from the wood without the risk of pushing some of the finish off.

The second factor is surface preparation. Peeling issues can occur if cleaner residue remains on the surface of the wood after cleaning, an inappropriate cleaner like bleach was used to clean the wood without thoroughly rinsing and neutralizing it, or the surface was sanded too smooth before application. The presence of mill glaze, dirt, sanding du st or other contaminates may also prevent adequate adhesion of the finish to the wood. Proper adhesion of the first coat of finish will not be attained if the application is made to wet or damp wood.

st or other contaminates may also prevent adequate adhesion of the finish to the wood. Proper adhesion of the first coat of finish will not be attained if the application is made to wet or damp wood.

Once the checks and fissures have opened, and a new coat of finish is applied, peeling rarely becomes an issue. That’s because during the application process the finish now has an opportunity to get into them, forming a water resistant barrier between the surface of the cracks and the bare wood [Figure 4].

One of the reasons for back-brushing is to work the finish into the cracks and fissures, thus preventing water penetration into the wood. But if the wall has been recently washed, make sure that there is no water remaining in the checks and fissures and the wood around them is absolutely dry before you apply the first coat of finish.

Some factors that can contribute to peeling include:

1. Surface improperly prepared

a. Contaminates like oil or wax

b. Mill glaze

c. Sanding dust

d. Sanded too smooth

2. Inappropriate products used

a. Bleach solutions

b. Caustic strippers

c. High pH cleaners

3. Inadequate rinsing

4. Application errors

a. Spraying without back-brushing

b. Product applied too thick

c. Application at too high or too low a temperature

d. Product applied to wet or damp wood

5. Freshly opened fissures/checks

a. Exposed to rain and direct sunlight

For information about repairs, see “Repairing Peeled Spots.”