Backing Material - Why You Need It

Backing materials are an integral part of a sealant system and should be used wherever possible. The overall performance of any sealant system is dependent on the use of correct application thickness and proper backing. Backing materials furnish an even surface for the application of a sealant and make it easier to apply a uniform thickness across the joint or gap. They also provide two-point adhesion to ensure maximum elasticity and flexibility after the sealant has cured (they form a bond breaker in the center of the sealant band with adhesion to the wood at both sides). The use of improper or poorly installed backing materials can result in unsightly sealant joints and substandard performance. They are an integral part of the sealant system and should always be used whenever and wherever possible.

For small joinery the most used backing is round backer rod. It comes in a range of sizes and is relatively inexpensive. It is flexible and can be pushed into a crevice without needing to be nailed or stapled. In situations where joinery is too narrow to insert some type of backing material, a narrow strip of water resistant masking tape works well. (Avoid masking tape that wrinkles when wet because the wrinkles may show through the sealant after it has cured.) A good option is to use pinstripe tape available at most automotive supply stores. The tape should be water resistant, so Energy Seal does not adhere to it, making it a suitable backer material. Pinstripe tape is available in widths down to 1/8".

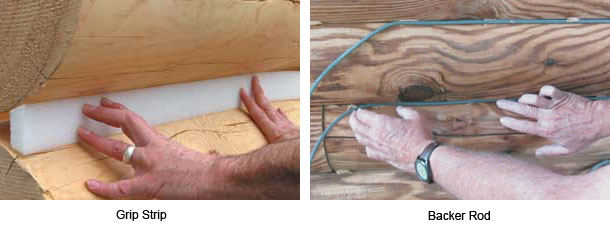

There are a number of products specifically designed for use as backing materials for sealants. For smaller gaps, joints and cracks the most commonly used material is round backer rod. It comes in a range of sizes and is relatively inexpensive. Since it is flexible it can be pushed into a crevice without needing to be nailed or stapled. Grip Strip is designed for sealing larger gaps. Similar in composition to backer rod, it is shaped like a trapezoid so it can be squeezed in between round logs although it can be used in a variety of situations.

Approved Backing Materials

- Grip Strip

- Backer Rod

- Log Gap Cap

- Polyisocyanurate board (Polyiso or R Max)

- Extruded polystyrene (non-foil EPS)

- Water-resistant masking tape or pinstripe tape

DO NOT USE: Expanded Polystyrene (causes blisters), Polyurethane foam (Pur Fill, Great Stuff, Styrofoam), Blue Board, Pink Board or other colored board that outgases to cause blisters. If you are unsure about your backing material, check with Perma-Chink Systems before using it.