Many general-purpose caulks never mention the use of backing materials on their labels. When applied to wood, any type of sealant, be it a high-quality Perma-Chink Systems’ sealant or an inexpensive construction caulk, will perform better if a backing material is used in joints that are 1/4” or greater wide. We want our customers to know the proper and best way to seal a joint so that it does not fail.

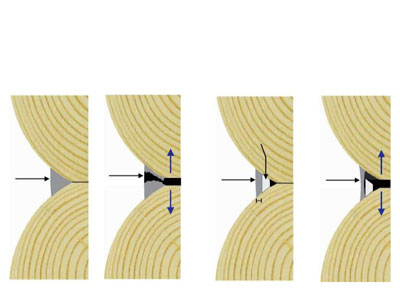

The use of backing material behind a sealant serves two purposes; First, to assure the proper thickness of the sealant so that it can stretch and contract without breaking; and second, to provide a surface that the sealant will not bond to so that it can stretch without tearing away from the wood. The dynamics of sealing an exterior joint or crack in wood is the same regardless of the width of the gap or the product being used. If the wood is unseasoned at the time a sealant is applied, the wood will shrink with time.

To compensate for the shrinkage the sealant must be applied in a manner that will allow it to stretch. When a sealant is applied too thick, once it cures it will not be able to stretch to compensate for the wood's shrinkage and may fail. When applied too thin, it becomes too weak to stretch without breaking. Think of it like a rubber band. A thick rubber band cannot stretch as far as a thin one. However, if the rubber band is too thin, it will break when it is stretched. If applied too thick they can not stretch without tearing and if too thin they will be weak and will tear when pulled apart. In the case of sealants manufactured by Perma-Chink Systems, the magic number is an applied wet thickness of 3/8”. This results in a cured sealant with excellent elongation and maximum strength.

Backing Materials

Backing materials serve to provide a suitable sealant thickness and surface for the proper application and performance of the sealant. A variety of materials can be successfully used. Some important features of a good backing material include:

- It must be inert, not outgas, or react with the sealant.

- The sealant should not adhere strongly to it.

- It should not wrinkle or deform when the sealant is applied over it.

- It needs to be able to withstand temperatures of at least 190 degrees Fahrenheit

There are several products specifically designed for use as backing materials for sealants. For smaller gaps, joints and cracks the most commonly used material is round backer rod. It comes in a range of sizes and is relatively inexpensive. Since it is flexible it can be pushed into a crevice without needing to be nailed or stapled. Grip Strip is designed for sealing larger gaps. Similar in composition to backer rod, but shaped like a trapezoid so it can be squeezed in between round logs. It can be used for a variety of situations to provide a flat surface for chinking or sealing.

For wide chink joints between squared logs, we typically recommend the use of polyisocyanurate board (polyiso or R Max) or expanded polystyrene (EPS) beadboard. When cured, the sealant should release from the backing material. If the sealant stays adhered to the backing material, this places much more demand on the sealant at the top and bottom of the joint. Failure is often the result of improper backing materials being used.

Materials that should never be used as backing include Blueboard or any other colored beadboard (they outgas and create blisters in the sealant), open cell foams (they absorb water), foil-faced extruded polystyrene (XPS) (causes blisters) or anything that you are not sure about.

Avoid foil-faced materials as the chinking will adhere tightly to the foil. This will interfere with joint movement across the entire joint placing more stress on the top and bottom of the joint. If you are unsure or need assistance with selecting the proper backing material, give us a call, and one of our technical representatives will assist you in determining the proper backing material.

What about joints that are too narrow to insert even the smallest diameter backer rod? In these situations, a narrow strip of water-resistant masking tape works quite well. You do not want to use regular masking tape that wrinkles when it gets wet. The wrinkles may show through the sealant. An excellent option is to use pinstripe tape available at most automotive supply stores. The tape is vinyl, so it is waterproof and our sealants will not adhere to it. Pinstripe tape is available in widths down to 1/8”.