Applications of all Perma-Chink exterior finish removers, cleaners, stains, topcoats and sealants can be a bit of a challenge in extremely hot weather, which we consider over 90°F. However, if you know what to expect and avoid you can easily cope with applications during the hot summer months. We’ll address each of our product lines individually. And for all our products, we recommend keeping the product pails out of the direct sun on hot days to minimize the heat build-up.

Finish Removers

Although finish removers work better at higher temperatures than cold ones, in order for them to continue doing their job they must remain damp. If you allow them to dry out they will no longer work. In the case of S-100®, if it is a very hot, dry day you should mist the wall with water prior to applying the S-100. This will help cool the wall down and extend the time before it starts to dry out. If you see it beginning to dry, lightly mist it with water. Just be sure not to apply so much water that it starts to run down the wall.

StripIt® is a bit more resistant to drying out than S-100. However, when exposed to direct sunlight it will start to dry out, stop working, and turn into a white, powdery coating. If it does appear that it’s drying, apply an additional application of StripIt to keep it wet, or cover it with plastic film. Do not mist StripIt with water.

If S-100 or StripIt completely dries on the chinking, sealants or wood, reapply some chemical stripper to aid in solubilizing the dried residue and remove with a pressure washer.

Cleaners

Like the finish removers, cleaners also stop working if they dry out. Keep Wood ReNew™ and Log Wash™ damp with a light mist of water until it’s time to wash them off. The same thing applies to Oxcon™ if it’s used. It’s especially important to keep Oxcon wet. If it dries and crystallizes on the wood the resultant oxalic crystals become very difficult to rinse off.

Stains and Topcoats

It is the surface temperature of the wall that has the largest impact on the application of a Lifeline stain or topcoat in hot weather. The hotter the surface temperature, the faster the water will evaporate and the finish will dry. It is not unusual for log surface temperatures to exceed 170°F when exposed to hot sunlight. At these temperatures, drying times can be reduced to a matter of seconds, too fast for adequate back-brushing and proper film formation. Once the finish is on the wall, it does not really matter if it gets hit by hot, direct sunlight. It’s the surface temperature during the application process that’s critical. On the south and west walls it may be best to start early in the morning while the walls are still cool. Later in the afternoon, even if the sun is no longer hitting the wall, the surface temperature may still be well over 100°F.

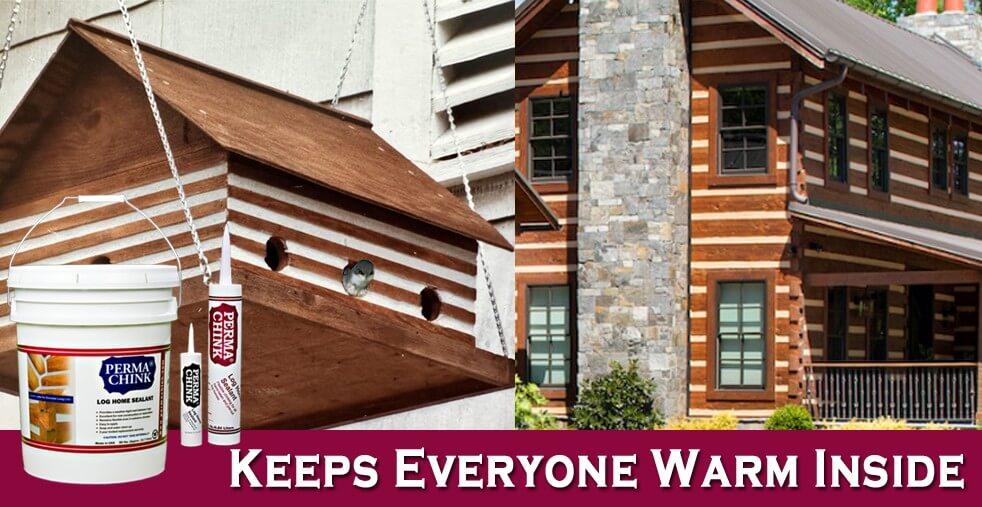

Sealants (Perma-Chink®, Energy Seal™, Woodsman™, Check Mate 2®)

Sealants are more sensitive to direct sunlight even in cooler temperatures than they are to heat, in general. That’s because direct sunlight accelerates the “skinning over” of the sealant, trapping the water contained within the product. When this water converts to water vapor and tries to escape from the product, it can create bubbles or blisters on the surface of the sealant. High ambient temperatures do influence the viscosity of sealants; they become more fluid, but for the most part they can still be successfully applied even when the temperature exceeds 90°F as long as the freshly applied product is protected from direct sunlight.