Drying times and curing times relate to two entirely different processes that occur in water-based polymer systems. All water-based products, be it stains, paints, or sealants, contain a percentage of free water, hence their description as water-based.

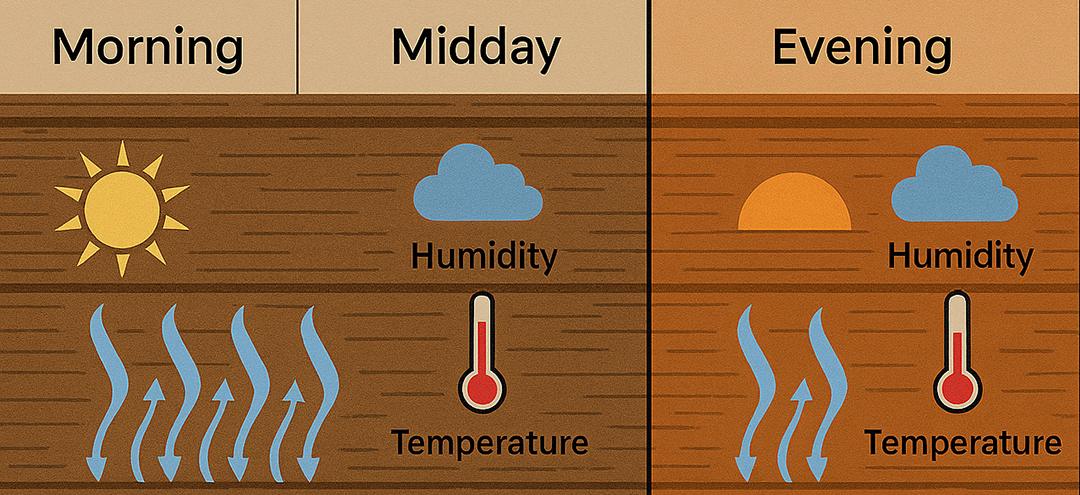

When applied and exposed to air, the free water begins to evaporate. The rate of evaporation is dependent on the humidity as well as the temperature. The higher the temperature and lower the humidity, the faster the rate of evaporation.

Once most of the water has evaporated from the surface, it feels dry – thus the term “dry to the touch.” The time a product takes to become dry to the touch is its “drying time,” although in the case of sealants, we typically talk about the time it takes a product to “skin over.”

Once a material has dried or skinned over, it does gain some strength in that it becomes impossible to brush out or tool smooth, but to achieve its maximum strength and durability it must be allowed to cure.

Curing time relates to the time it takes for a product to gain enough strength to withstand the parameters for which it was designed. As opposed to drying, curing is more of a chemical reaction that takes place on a molecular level. During the curing process environmental factors such as rain, snow, or high humidity can have a significant impact on the look or performance of a product. For example, in our Advance Topcoats, blushing is caused by water molecules becoming trapped within the polymer matrix during the curing process. Once trapped, it may take a long time for this water to escape from the film as long as environmental conditions remain cool and damp.

In addition to temperature and humidity, the time it takes sealants like Perma-Chink®, Energy Seal™, Woodsman™, and Check Mate 2® to cure depends on the thickness of their application. Once a sealant skins over, it inhibits the evaporation of water from the material under the skin. This prolongs the curing process, so although we may state that the curing time for Perma-Chink is two to eight weeks for a thinner or standard application, it may take several months for a 5/16” thick layer of Perma-Chink to attain its maximum strength.