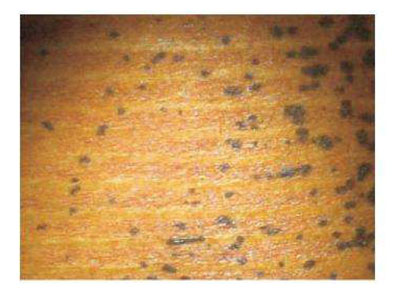

All wood contains tannic acid and when tannic acid comes to the surface, it can react with these metal particles creating dark color bodies or discolorations. There is much about this process that we have yet to understand but there are some things that we do know.

The first is that the application of chlorine bleach not only accelerates - and in many cases - initiates this process. The second is that direct sunlight intensifies the discolorations. That’s why the south and west walls are typically (but not always) more prone to discolorations than the north and east walls. The third is that areas of the log that cut through heartwood are usually worse than exposed sapwood. This makes sense, since heartwood contains a higher concentration of tannic acid than sapwood.

The Origin of Metallic Contamination

Milling, Planning and Shaping

All logs and siding used in a log home go through some type of process to remove the bark, cambium, and branches, and to also shape the wood. No matter what process is used, be it milling, planing, draw knifing, or even hand hewing, some type of steel blade is involved. Although you may not be able to see them, microscopic particles of steel are deposited on the surface as the blade or blades cut through the wood. If the blades on a milling machine, for example, get dull, many times more particles of steel will shear off as opposed to when the blades are sharp.

Using the Wrong Materials

Using wire brushes, steel wool or metallic abrasives to aid in the removal process of old finishes, or smooth the surface, will definitely create discoloration problems. Small bits of metal will be deposited on the wood and the use of these materials should be avoided at all costs.

Sandpaper and Sanding Pads

Although the use of most sandpaper and sanding pads present no risk to the formation of discolorations, it is not out of the realm of possibility for them to be a source of metal contamination, especially if they have been previously used. Let’s say a sanding belt was used to remove rust from a steel plate and then used again on a log home. Thousands of small metallic particles will be forced into the wood fibers. The same thing can happen if a sander or sanding disk goes over a nail or screw during the course of sanding a wall. The metal contamination will then be spread over a wide area. We also believe that there are some types or brands of sandpaper that may contain metallic particles along with the abrasives, but at this time we have not specifically identified them.

Contaminated Blasting Media

Blasting media like crushed glass is very abrasive and since it maintains its abrasiveness even after being used, some people try to reclaim and reuse it several times. If done once or twice, it usually does not present a problem but when reused multiple times it can become contaminated with metal as it flowed through the blaster pot, valves, and connections. It can also pick up contamination from the ground when it is reclaimed.

Installation of Steel Roofs and Other Metal Components

You can easily envision the amount of metallic dust and particles generated by cutting or sawing steel roof panels. They may well end up on the surface of your logs or even more likely, your deck. If they are not completely washed away, they will become a source of discolorations. Fortunately, we have never seen any discolorations associated with particles of aluminum. But any metal that contains iron has the potential for creating dark discolorations.

Preventing Discolorations Due to Contamination

The best way of preventing metallic tannate discolorations is to avoid contaminating the surface in the first place. In the case of metallic particles deposited during the shaping process, well, that’s impossible. Wood surfaces should always be thoroughly cleaned with Log Wash™, or in the case of milled log siding, Wood ReNew™, before the first coat of finish is applied.

Steps to Take to Avoid Metallic Contamination:

- Never use a wire brush or steel wool on a wood surface that’s going to be finished.

- Use good quality sandpaper and sanding pads specified for use on wood and never use any that have been previously used for another purpose. Store them separately in plastic bags and don’t allow the abrasive side to contact any metal prior to use.

- If during sanding you run over a nail or screw, discard the paper or pad.

- Do not attempt to reuse blasting media more than two times, and avoid picking up dirt or other contaminates as you reclaim it.

- Wood surfaces should always be thoroughly cleaned with Log Wash, Cedar Wash (for specific wood species like Western Red Cedar), or Wood ReNew before the first coat of finish is applied.

|

|

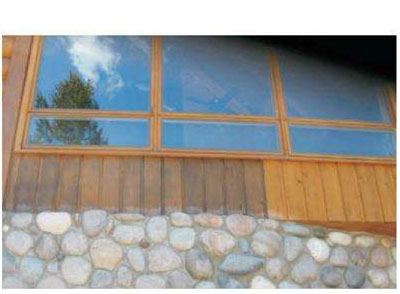

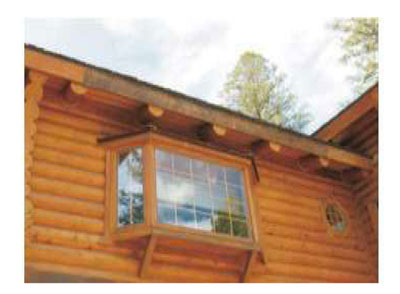

| Spots created by steel wool | Dark section was wire-brushed |

|

|

| Section of facia that was wire-brushed | Metallic tannate discolortions from unknown source |