There is not much anyone can do in these situations. The problem is related to the quality of the siding and the way it was installed. Even a sealant with 1000% elongation would not be able to handle the dynamics encountered in these circumstances. Trying to keep up with the gaps as they develop is an exercise in futility. It is a lot less work to wait until the siding has finished shrinking and moving and then address sealing the gaps using the appropriate backing materials.

There is not much anyone can do in these situations. The problem is related to the quality of the siding and the way it was installed. Even a sealant with 1000% elongation would not be able to handle the dynamics encountered in these circumstances. Trying to keep up with the gaps as they develop is an exercise in futility. It is a lot less work to wait until the siding has finished shrinking and moving and then address sealing the gaps using the appropriate backing materials.

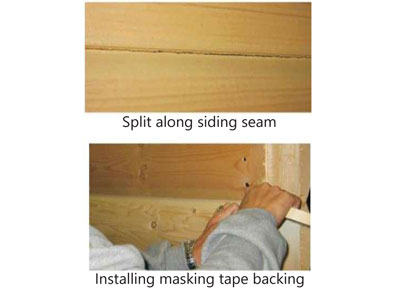

Another problem encountered when sealing log siding is that its design rarely leaves enough room for Backer Rod or other types of backing materials. If no backer is used, even a small amount of shrinkage will result in a split forming in the sealant along the seam. About the only thing that can be done to avoid this from occurring is to run a strip of masking tape along the seam and then trim the tape to the desired width.

Pinstripe tape available at most auto supply stores also works well. Don’t forget that you will need at least 1/4 inch of bare wood above and below the tape for the sealant to adhere to, while maintaining a wet sealant thickness of 3/8 inch. This will allow some movement of the siding without the sealant splitting along the seam.

The last topic about sealing log siding has to do with the siding ends. Just like logs, the exposed end grain of siding is prone to absorb water. Once the window, door, and corner trim is installed, it is almost impossible to completely protect the ends of the siding from contact with rainwater. This is especially true on dormers and other exposed areas of a home. The consequences of water absorption from the end grain include finish adhesion failures and dark discolorations due to water infiltration. However, if the ends of the log siding are coated with Log End Seal™ after staining, water absorption by the end grain will no longer be an issue. But to do it properly the siding will have to be stained and the Log End Seal applied before the trim-work is installed.

Tip: Stain all six sides of the wood siding prior to installation to prevent water vapor from pushing through the back side of the wood siding and negatively impacting the finish system.