Resin is made of up of a combination of rosin acids, fatty acids, and hydrocarbon compounds. It is produced by most trees, but particularly softwood species like spruce, pine and fir. Amber is fossilized tree resin.

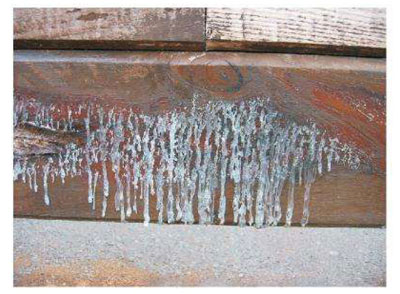

One problem with resin bleed is that the log may continue to bleed each summer for many, many years. Most of the time it’s just a few logs on a wall that bleed resin, but occasionally we do encounter a log home where just about every log or knot on a south or west facing wall bleeds resin, and when that happens, it can be very unsightly. There is no way to outwardly determine if a log will bleed resin or not.

Trees may form pockets of resin due to a past injury, or for a variety of other reasons, and when that tree is harvested it may take months or even years for the resulting log to begin to bleed resin. Tree resin is typically thick and viscous, but gets quite thin when heated. During the summer months, logs on the sunny sides of homes get hot enough for pockets of resin to thin and bleed out of the wood. Once this begins, it is virtually impossible to halt the flow of the resin out of the wood. It will easily burst through coatings like paint or stain due to its highly acidic nature, and form an ugly, sticky mass on top of the finish.

So is there anything that can be done about resin, pitch, or sap bleed? Since the resin is soft and sticky, it is impossible to wipe off the surface without making an even bigger mess. It’s not water soluble, so it can’t be washed off. Small spots of resin can sometimes be cleaned off with alcohol or other organic solvents (i.e. xylene or toluene), but if there is a finish present, the alcohol or organic solvents can also degrade the existing finish.

It is important to remove any remaining solvent residue that could possibly interfere with the adhesion of the reapplied finish. The only effective method of removing resin that we are aware of is to chip it off, but in order to do this the resin must be cold enough to become brittle. In the north, it’s best to wait for a cold winter day, but in the south, cold days are few and far between. In warmer climates, you can use an ice pack to cool down the resin then try to chip it off. Sometimes this works and sometimes it doesn’t, but it may be worth a try. The problem is that come summer, the bleeding will most likely start up again.

One of the biggest challenges relating to resin bleed is when it occurs on bare wood prior to the application of a finish. Since there is no effective way to totally remove the resin, the finish ends up being applied on top of it. When the wall heats up and the resin starts to flow, it carries the finish along with it leaving unsightly spots of exposed bare wood. Again, there is not much that can be done to end this process until the resin eventually stops bleeding out of the wood.