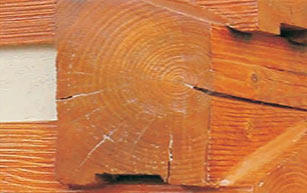

The first step when applying Log End Seal is to sand the log ends smooth with a belt or orbital sander or sanding disks (available here). Take care not to leave any deep sanding marks or gouges. Most log homes arrive with the log ends sawn off to the proper length. The sawing may leave a rough surface and when stained the log ends typically end up being much darker than the smooth sides. A log end that has been sanded smooth and then stained will be much closer in color to the log walls.

Applying Log End Seal

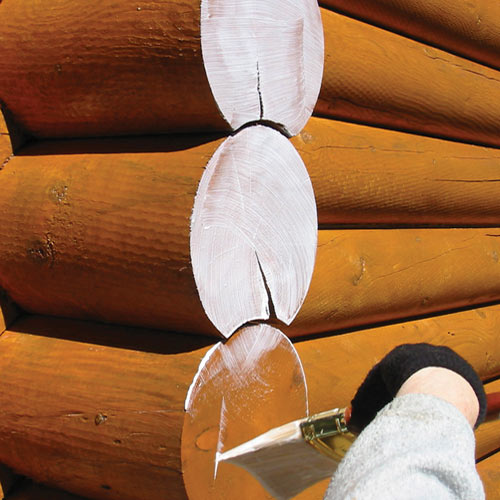

Once the log ends are sanded and one of our LIFELINE brand stains is applied to the home and allowed to dry, you are ready to put Log End Seal on the exposed ends. Although you can use a short-bristled brush to apply Log End Seal, we found that an applicator pad works best. Be sure to coat the entire face of each log end to avoid any uncoated spots. Wipe off any excess that may have dripped onto the sides of the logs with a damp rag.

Allow the Log End Seal to dry to the touch and finish the job with LIFELINE Advance clear topcoat in gloss or satin.

Drying and Curing Time

Once Log End Seal dries and cures, it may take a while before it loses its milky appearance, especially in checks and fissures. But the end result will be an appealing, clear surface that will offer the utmost protection to the ends of your logs.

Download the application steps of Log End Seal here: Log End Seal Tech Tip