All too often a homeowner has no idea what is on the walls, let alone how many coats were applied. What they do know is that they want to apply something on top of what’s already there to avoid the cost and effort of stripping the surface down to bare wood. This approach is very risky, especially with a water-based, high performance film-forming finish like Lifeline.

Let’s look at some of the individual parameters that have to be dealt with and addressed.

Appearance

Perma-Chink’s Lifeline stains are transparent finish systems. This means that any discolorations or residual pigmentation that remains on the wood will show through our finish systems. With few exceptions, our finishes have little or no hiding power. Once our Lifeline system has been applied, it essentially locks the surface of the wood in place. If you are dissatisfied with the final look and appearance, it can be quite costly and time consuming to remove the finish, address of the discolorations, and refinish the wood surface.

Adhesion

How much residual oil still remains in the wood and is it enough to interfere with the adhesion of Lifeline stain? These are questions that are just about impossible to answer. Yes, a small test area may quickly determine that there is a problem, but if a problem does not show up within a few days there is no way to tell what may happen over a period of several months or years. We have seen several issues that were directly attributed to the prior application of oil-based or petroleum stains. Peeling occurred around checks and micro-fissures because they had been flooded with an oil-based product during the initial staining process, and although most of the oil had evaporated from the surface of the logs, the checks had retained enough oil to reduce the adhesion of a water-based film.

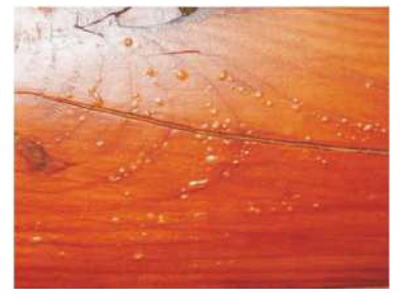

Blisters

When several coats of an oil-based, or petroleum, penetrating stain have been applied to a wall within the course of a few years, the underlying wood can become so saturated with oil that it may take a long time for it to evaporate. When a homeowner finally decides that it is time to change to a quality finish like Lifeline, pressure washing with just water, or even a mild detergent, may appear to remove most of the residual oil and colorants, and give the appearance of a prepared surface for the Lifeline finish. The wood may look clean and bare, but in reality the old oil carriers may still be in the top layer of wood. With the application of the first coat of Lifeline, these oils are now trapped in the wood and serve as a vapor barrier. Yes, our finishes breathe water vapor, but oil molecules are much larger and can’t make it through the film.

Now weather comes into the equation. If the days stay cool and cloudy until the entire finish system is applied and has time to cure, there’s a good chance that nothing of consequence will occur. But if the sun comes out and heats up the wall while the finish is still soft and pliable, the oils contained in the wood will begin to evaporate, creating blisters in the finish. This can occur after the first coat, second coat, or even after the entire finish system has been applied. One thing that these types of problems have in common is that they typically show up within a week after application.

If you plan to apply Lifeline after having applied a penetrating oil-based stain, what is the best way to minimize the chance of forming blisters? The product to use in these cases is S-100™ Finish Remover. S-100’s formulation includes a strong and aggressive detergent package that will help make the residual oils water soluble and easier to remove and wash away from the wood surface.

Once the finish is removed using S-100, allow the surface to remain bare for a couple of months to allow any remaining oil to evaporate. When you are ready to stain, wash the surface with Log Wash™, allow it to dry and apply the first coat of Lifeline.