Perma-Chink Systems, Inc

Log & Timber Home Care Experts

Perma-Chink Systems, Inc

Log & Timber Home Care Experts

Michael

Although it has been over ten years since we made our last batch of Proguard™, we still get occasional calls relating to the application of our stains over surfaces top-coated with Proguard.

NBS-30

NBS-30 is an oil-based insecticide additive for paints and stains. Pure and simple, oils and water do not work together and we DO NOT approve the use of NBS-30 in any of our finishes.

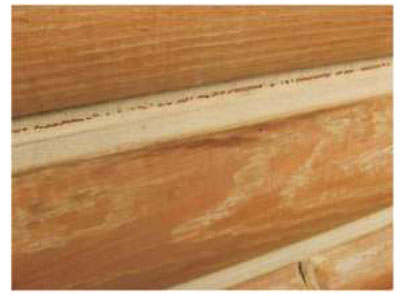

Log siding presents much more of a sealing challenge than stacked logs for several reasons. As stacked logs season and shrink, they settle on top of each other. If there are sealed gaps between the logs, the width of the gaps between the logs may remain fairly uniform as the logs settle. On the other hand, log siding is nailed or screwed into dimensional lumber which holds the siding in place. As shrinkage occurs, the gaps between the courses can become wider and wider (see pictures below). In addition, if the siding is not properly attached to the wall, it can twist and warp, creating even larger gaps between the courses.

Occasionally we get a call from someone whose home has a gray aged patina that appeals to them. They typically want to apply some type of clear water repellent to seal and protect their home, but they don’t want to remove the grayed wood. The gray color is an indication that the surface wood has been photo-oxidized by ultraviolet (UV) light and the wood fibers have lost their integrity.

Sealers

“Which of your products should I use to seal my log home?” is a question often put to us by prospective customers. Why do so many people refer to “sealing” a log home rather than staining or finishing? Nobody talks about sealing siding or trim on a stick built home. They are either stained or painted, yet sealing is the term used by many log home owners. As it relates to log homes the term “sealing” dates back to the early 1900s. Prior to then, most log homes were constructed using heartwood from old growth timber and left bare.

Hand sanding is a commonly used technique to prepare wood surfaces for a coat of finish. Sanding may be used after media blasting, pressure washing or to touch up areas that are needing maintenance or repair. One common mistake is to sand the surface as smooth as possible.

How Do Rips and Tears Happen?

Occasionally rips and tears form in log home chinking, especially in new homes that have been constructed with fairly green wood. Most of the time these tears appear on the top edge of the chink joint. That’s because during the tooling process, most people tend to pull product from the top to the bottom of the chink joint, which results in a thinner than recommended layer of chinking along the top edge. In addition, people forget to “push” the chinking up against the top edge, resulting in inadequate adhesion. When the logs shrink, it puts a strain on the chinking and if it was not properly applied, it can pull away from the wood. So when working Perma-Chink®, it is important to keep pushing the product towards the top of the joint.

Occasionally rips and tears form in log home chinking, especially in new homes that have been constructed with fairly green wood. Most of the time these tears appear on the top edge of the chink joint. That’s because during the tooling process, most people tend to pull product from the top to the bottom of the chink joint, which results in a thinner than recommended layer of chinking along the top edge. In addition, people forget to “push” the chinking up against the top edge, resulting in inadequate adhesion. When the logs shrink, it puts a strain on the chinking and if it was not properly applied, it can pull away from the wood. So when working Perma-Chink®, it is important to keep pushing the product towards the top of the joint.

Do you need to remove any caulk that’s already in place before applying Energy Seal™, Woodsman™, or Check Mate 2®? Applying new sealant over old caulking is never a good idea, even if it looks like the old caulk is still sticking to the wood. The old caulk should be removed for several reasons.

All of our stains and sealants are water-based, and while they are still wet, most clean up quite easily with just soap and water. That’s usually the best method to use for cleaning our wet, uncured products off of windows, gutters, downspouts, and other smooth surfaces, but there are occasions when other clean-up techniques should be used to remove some of our textured sealants from wood surfaces.

Although we have never identified exactly what it is, there is a magical ingredient in Perma-Chink that acts as a magnet to human fingers. Put an adult or juvenile male anywhere close to a wall with a fresh application of Perma-Chink, and the first thing that happens is one hand comes out of their pocket with one or more fingers magnetically attracted to the chink joint.

New Age Blast Media Available Sizes

Call 1-800-548-3554 to Order

Features

- Made from recycled glass

- Superior to corn, walnut, sand or soda media